New & Noteworthy

Resistance is Not Futile: How Yeasts Avoid Getting Ill from IILs

September 24, 2018

In the Batman comics, Poison Ivy is resistant to all natural toxins and diseases (from deviantart)

Resistance to poisoning is a good thing in the cartoon world, where both good and bad guys and gals often have superpowers that render them resistant to all sorts of toxins and poisons. But does that happen in the “real” world that we live in?

Well, some people would say that Keith Richards and cockroaches are the ultimate examples of earthly organisms resistant to every known toxin! But there are other more mundane examples of humans that are resistant or tolerant to certain chemical or organic compounds.

For example, almost everyone knows someone (or themselves) who can’t drink milk, because if they do, they feel really sick, with uncomfortable or even severe gastrointestinal symptoms. These people are said to be “lactose intolerant” (which is NOT an allergy to milk), because their gut can’t digest a sugar called lactose found only in milk and milk-based products.

Interestingly, all humans have the “lactase” gene that allows their body to digest lactose, but lactose intolerant folks have a particular “switch” sequence in their DNA that causes the gene to get totally turned off once they’re not babies anymore.

The lactase enzyme splits the disaccharide lactose into galactcose (1) plus glucose (2) (from wikimedia)

However, people who CAN drink milk as adults (“lactose tolerant” people) have a change in their DNA sequence that inactivates the switch. So these people have the lactose-digesting gene turned on and functioning for their whole lives and can consume milk and dairy products even as adults.

This is an example of genomic diversity among human beings, where people’s individual genome sequences have differences that can make them resistant to the negative effects of some foods or chemicals, while other people have little or no tolerance at all.

This type of DNA sequence variation across all the members of a species is called “standing genetic variation” and it’s a very good thing. Why? Because when a changing or novel environment challenges a population, standing genetic variation increases the chance that some individuals can adapt to new types of foods (like what happened with the lactase gene) or have other characteristics that make them better suited to survive in the new environment…or even be resistant to new diseases!

In the Planet of the Apes series, “simian flu” kills almost all humans except for those few who are resistant (from deviantart)

But what does all of this have to do with yeast? Well, just like lactose intolerant humans, yeast can get sick when they try to “eat” certain things too, and will fail to grow well in the presence of such compounds. But could there be some yeast individuals somewhere in the world that have tolerance to certain normally-toxic compounds?

This is exactly the question that Higgins and co-workers asked, and in the September issue of Genetics they describe how they found naturally occurring yeast that can tolerate high levels of compounds called “ionic liquids.” And they also discovered the underlying naturally-occurring genetic variations in two genes that make the yeasts more tolerant to these compounds!

So what are ionic liquids and why were these investigators interested in them? Ionic liquids are a type of salt that can exist in a liquid state at temperatures under the boiling point of water or even at room temperature.

One type in particular, “imidizolium ionic liquids” (IILs) are often used in production of biofuels because they efficiently solubilize plant biomass cellulose and help turn it into glucose. The glucose can then be fermented (often by our yeast friend Saccharomyces cerevisiae) into bioethanol or other biofuels.

However, most commonly used S. cerevisiae strains, when grown in the presence of IILs, get very ill. But if IIL-tolerant yeasts could be found, they could help improve the production of cellulosic ethanol and other bioproducts.

Cellulosic biofuels may help decrease worldwide carbon emissions by reducing fossil fuel use (from wikimedia)

Higgins and co-workers decided to make use of the standing genetic variation within the S. cerevisiae species by taking hundreds of different strains of S. cerevisiae, isolated from around the world, and seeing if any of them could grow better in the presence of IILs.

And indeed they found some strains that were extremely IIL-tolerant compared to other S. cerevisiae strains such as beer, wine or lab strains, or even those commonly used in biofuel production! The yeast strain that was the most IIL-tolerant was, surprisingly, a clinical isolate from Newcastle, England.

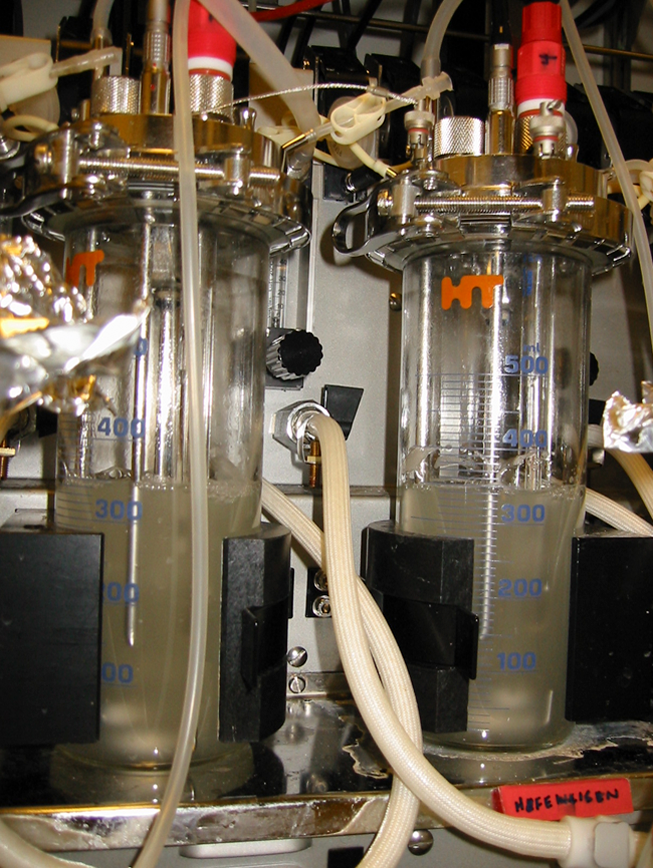

The researchers then took genomic DNA from this IIL-tolerant strain and chopped it up into large pieces and put the pieces (carried on special plasmids called fosmids) into the common S288C lab strain (which is intolerant to high IILs) to see which regions could allow the lab strain to now grow in the presence of high levels of IILs.

They found two genes that conferred tolerance to the IILs: the SGE1 gene, plus a previously unnamed gene, YDR090C, which had not been studied very much. The proteins made from both genes appear to be located in the plasma membrane of the cell. The authors propose that the tolerant version of the SGE1 protein, already known to be a multidrug efflux pump that exports toxic cationic dyes out of the cytoplasm, is directly involved in the pumping the IILs out of the cells to help yeast tolerate these toxic compounds.

The Sge1 protein is a multidrug transporter. Similar proteins in humans can cause resistance to anti-cancer drugs (from wikimedia)

The researchers were not able to exactly figure out what YDR090C is doing in the membrane to help cells be resistant to the bad effects of IILs, but they did find out that cells with a deletion of the gene were less tolerant to IILs. They thus named this gene “ILT1” for “Ionic Liquid Tolerant”.

The authors also found that the SGE1 gene from the IIL-resistant “wild” strain from England had a change in its protein sequence relative to the lab strain, but rather than making the protein more efficient at pumping, it looks like the changed protein is more abundant in the cell and thus can just pump out more of the obnoxious IILs.

Whenever they put this resistant gene version into an IIL-intolerant yeast, it did the trick of allowing the strain to grow better in high IILs concentration. This discovery might allow greater use of IIL-treated biomass for the production of biofuels, as it shows one powerful method of increasing the tolerance of biofuel-producing yeast to toxic IILs.

So this is indeed a case where looking at the “standing genetic variation” of a species has helped discover new and useful biotechnological functions in yeast, and also shown us that resistance (to IILs at least) is NOT futile, and may indeed help us make yeast more efficient at making more biofuels!

Resistance might be futile if you’re up against the Borg, but at least yeast can resist IILs!

by Barbara Dunn, Ph.D. and Kevin MacPherson, M.S.

Categories: Research Spotlight

Tags: biofuels, lignocellulosic biomass, variation

Too Big for the Oven

March 23, 2017

Just like baking bread, “oven” size matters when trying to increase yields of fatty acids in yeast.

In a classic skit from I Love Lucy, Lucy bakes a loaf of bread that is so big it ends up coming out of the oven, pushing her against the far wall. Definitely one of the funniest moments from early TV.

In a new study in Nature Communications, Gajewski and coworkers show that the yeast enzyme fatty acid synthase (FAS) complex, is a bit less comical when it comes to the fatty acid chains it makes. When these authors engineer the enzyme complex to “shrink” the oven, the “bread” it makes becomes smaller. A more constrained active site that holds onto its growing fatty acids less tightly makes shorter-chained fatty acids.

This is an important finding because these shorter-chained fatty acids are so useful as precursors for products like biofuels. Engineered yeast like these may, among other things, one day help us get to a carbon neutral future.

Gajewski and coworkers were able to pull this off because the 3-D structure of this enzyme complex is so well understood. They engineered changes that would be predicted to restrict the growth of the fatty acid chain.

For example, a key player in the elongation step happens in the condensation domain (KD) of the complex. They focused initially on the amino acid methionine at position 1251 (M1251).

This amino acid sticks out into the active site and needs to rotate out of the way when the fatty acid chain elongates. The authors reasoned that if they made it bigger and harder to rotate, the enzyme complex wouldn’t be as good at elongating the fatty acid chains it makes. The loaf would stop growing when it ran out of room.

They were right. When they mutated a nearby glycine to serine (G1250S), the yeast now made 15.3 mg/liter of fatty acids with 6 carbons (C6 fatty acids), a 9-fold increase over wild type. FAS usually makes C12-C18 fatty acids.

Tomorrow’s oil wells? By (Image: Maitreya Dunham) [CC BY 2.5], via Wikimedia Commons

They got even better results when they bulked up position 1251 by changing the methionine to a tryptophan (M1251W). Now the yeast made 19.1 mg/liter of C6 fatty acids, a 12-fold increase, and 32.7 mg/liter of C8 fatty acids, a 56-fold increase. They made a third mutation, F1279Y, that ended up affecting growth adversely when combined with G1250S.

This was good, but not good enough. To be commercially viable, they needed higher yields. They next wanted to make mutations that would cause the enzyme complex to hold onto the fatty acids less tightly, like having the baker remove the bread from the oven before it got too big.

For this, they focused on the malonyl/palmitoyl transferase (MPT) domain. They reasoned that by making the complex less able to bind malonyl, it would also bind the growing fatty acid chain less well too. Again, they were right.

When they replaced an arginine with a lysine at position 1834 (R1834K), the yeast made 100 mg/liter of mostly C8 fatty acids, a 23-fold increase. They made an additional mutation, I306A, that had little effect on its own.

Things got really interesting when they looked at different combinations of these mutations. When they mixed and matched them, they pushed yields up even more. And different combinations made different proportions of various sized fatty acids. Scientists can pick the mutant that gives them their desired product.

The best yield was with yeast carrying the triple mutant, I306A-R1834K-G1250S. These yeast managed to make 118 mg/liter of shorter-chained fatty acids.

Gajewski and coworkers boosted this mutant’s yield even more by changing out the promoter. Doing so resulted in the yeast making 464.4 mg/liter of the enzyme.

We now have a strain of yeast that can make a lot of the precursors needed for making biofuels and other chemicals. And scientists can pick the mutant that gives them more of their desired precursor. If they want more C6, they should use one mutant and if they want more C8 they should use a different one.

#APOYG is helping to create designer molecules that could, among other things, help steer us toward a more carbon neutral future.

by Barry Starr, Ph.D., Director of Outreach Activities, Stanford Genetics

Categories: Research Spotlight

Tags: biofuels, fatty acid synthesis, precursor